Vertical Farms

Indoor agriculture has less risks than outdoor crop production. By controlling light exposure, temperature, humidity and watering levels, you can grow food very efficiently. Indoor farming has the potential to produce food with less energy, less water, less waste and in less space than traditional methods. And, of course, you can also grow vegetables in winter and vegetables which normaly doesn‘t grow in your area.

At the moment, there are mainly fast-growing vegetables planted, like leaf vegetables.

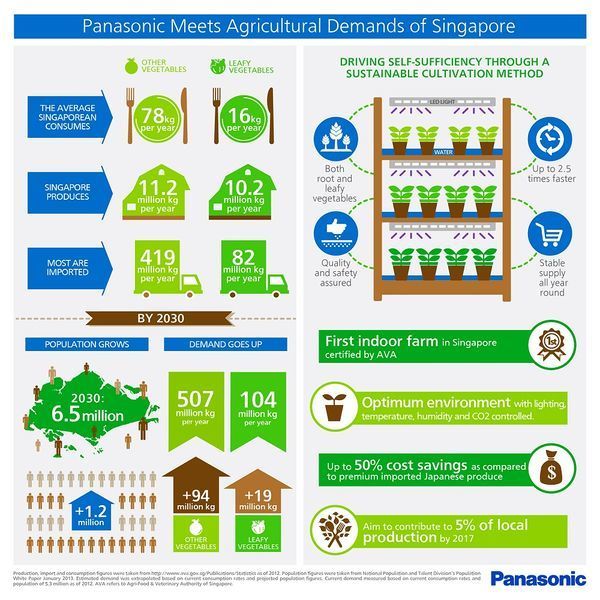

Panasonic foundet a vertical farm in Singapore in 2014. It is the country‘s first licensed indoor vegetable farm. This farm is in a building which contains thousands of LEDs which helps the plants to grow. This vertical farm grows 80 tons of vegetables every year. They grow 40 varieties of crops. The farmers can control the indoor farm’s climate – including pH levels, temperature, and oxygen. There are growing leaf and root vegetables and Panasonic is selling them under the brand name „Veggie Life“ in local supermarkets and restaurants. They are currently growing 0.015 percent of produce grown in the country but Panasonic want to boost the growth up to 5 percent. At this stage, Singapore imports more than 90 percent of its food, indoor farms could help Singapore to become more independent and, of course, more sustainable. With this kind of farming, they use less water and less arable land. And the crop is staying the same of long duration, so the crop isn‘t influenced by climate changes. Also the plants can clean the air in big cities with smog-problems and there is less pollution due to food transport. Of course they need energy for the facilities of the building but I think they need less energy for producing vegetables in this way than if they import the vegetables. But it would be even better if they use hydrocultures, they need 90 percent less water and fertilizer.

Panasonic thinks that this way of growing vegetables is the future.

An even bigger vertical farm is one located in a abandoned Sony workshop in Miyagi Prefecture, Japan, of the compani Mirai. There are 2300 square metre of base area and a ten times bigger area of cultivable land. There are 10 000 heads of lettuce gathered each day. That‘s 100 times more per square foot than traditional methods. 17,500 LED lights spread over 18 cultivation racks reaching 15 levels high. The LEDs are developed by GE for this project. They are imitating the wavelength of the daily light which are fitted to the needs of the plants. Mirai has succeeded in increasing harvest yields by 50 percent. The plants grow twice as fast with 40 percent less power, 80 percent less food waste and 99 percent less water usage than outdoor fields. The plants themselves are constantly irradiated with artificial light to make them think it’s sunny, while being injected with vitamins and nutrients directly into their roots, removing the need for soil. Shimura argues that their products are free of bacteria, fungi or insects and require no pesticides, making it an organic product with a extremely long shelf life. This system allows Mirai to grow lettuce two-and-a-half times faster than an outdoor farm.

Shimamura: “Finally, we are about to start the real agricultural industrialization.”

This way of planting is, for the first time ever, tested on the ISS in 2014. Of course due to space and loading weight problems on a rocket First of all, they sent the vegetables back to earth to analyze them. They didn‘t found critical substances in it. So back in 2015, astronauts have been allowed to eat the first spacelettuce. Of Course this were broadcast life. NASA want to research, in addition to nutritional benefits, the psychological impact of fresh vegetables and foliage plants to astronauts as well.

In my opinion, this is a good alternative for the future growth of vegetables, but you also have to think about how tho produce meat, I think that this is not possible to grow them like the plants in a indoor farm due to animal rights but there are also studies about breeding organs for transplantations and also meat. And there are also scientist, like the japanese medical scientist Makoto Nakamura, which are researching 3D printig organs and meat. It could be that the future steak is not a piece of a real animal but rather a piece of meat grown in the lab or even a 3D printed piece of meat.

Fact is, there will be a problem about getting enough food for everyone in the world due to overpopulation in the cities because there will be more people in the cities than in rural areas. There won‘t be enough arable land to feed them all. Indoor agriculture and 3D printed meat is a sustainable and space-saving local method of bringing food to the market.

http://www.straitstimes.com/business/panasonics-fresh-new-product-salads

http://news.panasonic.com/global/stories/2015/44449.html

http://inhabitat.com/singapores-giant-vertical-farm-grows-80-tons-of-vegetables-every-year/

http://www.ecowatch.com/worlds-largest-vegetable-factory-revolutionizes-indoor-farming-1882004257.html

http://www.spiegel.de/wissenschaft/weltall/internationale-raumstation-astronauten-kosten-erstmals-weltraum-salat-a-1047509.html

http://www.3ders.org/articles/20151020-3d-printed-lab-grown-meat-could-be-in-stores-in-the-next-five-years.html

http://inhabitat.com/the-worlds-largest-indoor-farm-produces-10000-heads-of-lettuce-a-day-in-japan/

https://www.youtube.com/watch?v=TVoV6u3vp8k&feature=youtu.be

http://www.planet-wissen.de/gesellschaft/medizin/organverpflanzung/pwieorganezuechten100.html

https://turbofuture.com/misc/Creating-Transplant-Organs-With-3D-Bioprinters